Ohio Bio-Enviro Settlements Inc.

Anaerobic Waste Digestion

Anaerobic digestion is a biological process that produces a gas principally composed of methane (CH4) and carbon dioxide (CO2) otherwise known as biogas. These gases are produced from organic wastes such as livestock manure, food processing waste, and the waste products produced in the home bathroom.

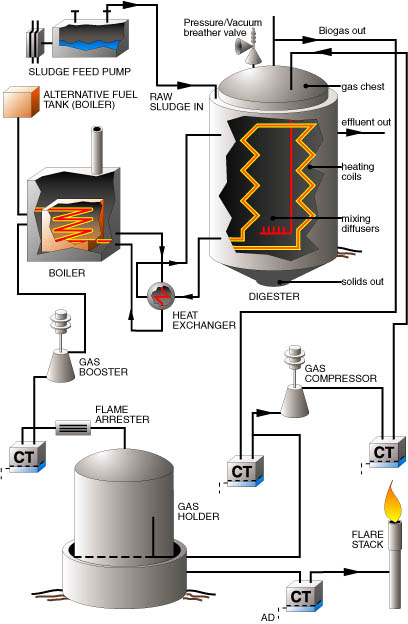

Anaerobic processes could either occur naturally or in a controlled environment such as a biogas plant. Organic waste such as livestock manure, human fecal material and various types of bacteria are put in an airtight container called a digester so the process could occur. Depending on the waste feedstock and the system design, biogas is typically 55 to 75 percent pure methane.

The process of anaerobic digestion consists of three steps.

The first step is the decomposition (hydrolysis) of plant or animal matter and waste products. This step breaks down the organic material to usable-sized molecules such as sugar.

The second step is the conversion of that decomposed matter to organic acids. And finally, the acids are converted to methane gas.

The third step has traditionally been to burn the gas as it is produced. We have changed this step, and intend to pump the Methane into holding tanks under pressure and then to pipe it to the homes, for cooking and the limited heating that each home will need. It will also provide the fuel for the PEM Fuel Cell.

Process temperature affects the rate of digestion and should be maintained in the mesophillic range (95 to 105 degrees Fahrenheit) with an optimum of 100 degrees F. It is possible to operate in the thermophillic range (135 to 145 degrees F), but the digestion process is subject to upset if not closely monitored. We will be opperating between the two ranges for optimum biogas output.

Most anaerobic digestion technologies are commercially available. Where unprocessed wastes cause odor and water pollution such as in large dairies, anaerobic digestion reduces the odor and liquid waste disposal problems and produces a biogas fuel that can be used for process heating and/or electricity generation.

A Typical System

Our Power House Design